- Profile, introduction, application, advantages, history, classification and future of 3D printer is presented on this page.

- 3D printer is a machine with ability of creating a physical object from a digital model based on Rapid prototyping technology. The machine is called 'Imprimante 3D' in French, 3D 打印机' in Chinese, '3D Drucker' in Germany, '3Dプリンタ' in Japanese. 3D printing technology appeared in the mid-1990s in the aerospace manufacturing industry.

-

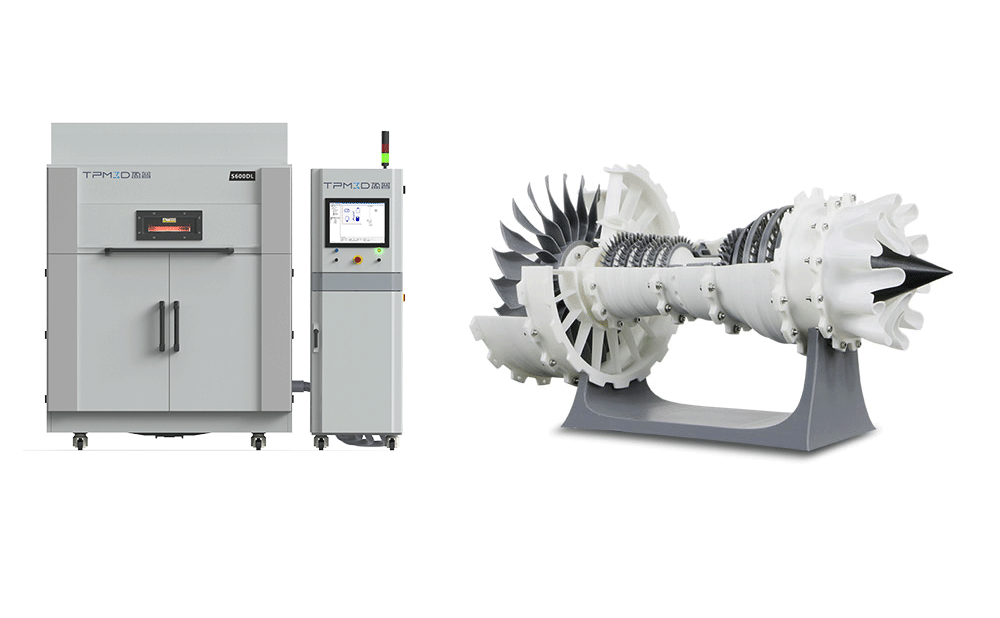

- The photo covers a 3D Pring Machine and a object printed by the printer.

-

Rapid Prototyping (RP), also known as Rapid Prototyping Manufacturing (RPM) technology, was born in the late 1980s. It is a high-tech manufacturing technology based on the material accumulation method. It is considered to a great achievement in the manufacturing field in the past 20 years.

3D printer is created based on above theory. The machine piped out powdered metal, plastic or other bonding material based on digital model file. The technology works by adding a new layer upon a previous layer of material to build up a complete object.

It works in the same way with ordinary printer. But the printing material need to be changed from ink to liquid, powder or other bond-able material. Printing materials need to be filled in the printer before it works. Controlled by computer, the 3D printer superimpose printing material layer by layer, till a finally the blueprint on the computer is turned into a real object. -

The following classification was divided based on Material, Bonding method, Melting and solidification.

1. Polymer polymerization: laser three-dimensional printing, Polymer Printing, Polymer Jetting, Digital Lighting Processing, Micro Stereolithography.

2. Sintering and melting: Selective Laser Sintering, Selective Laser Melting(SLM), Electron Beam Melting(EBM).

3. Adhesive powder : Three Dimensional Printing,

4. Fused Deposition Modeling, such as RepRap project,

5. Layer Laminate Manufacturing

6. Aerosol printing

7. Bioplotter

-

3D printing progress covers the following steps.

1. 3D Design

Set up a Three-dimensional file of the printing object via modeling software. The step told the computer what the object looks like.

2. Slicing

Divide three-dimensional model into layer-by-layer sections. The thickness of a general slice is 100 microns, or 0.1 mm. A high-precision printer can print a layer as thin as 16 microns. The diameter of the printed "ink drop" is usually 50 to 100 microns.

3. Print

The computer guide the printer to print the object slice by slice, till the whole object created.

- Medical field

- A Xian hospital of China 3D printed part of defect skull, which helped a local farm restore the condition of head.

- In August 2014, A research team from Peking University in China successfully implanted a 3D printed spine into a 12-year-old boy to help him recover from a football injury and the following Tumor.

- In October 2014, doctors and scientists used 3D printing technology to put the palms of a 5-year-old girl in Scotland.

- In August 2018, researchers of Minnesota 3D printed equipment to create a bioengineered spinal cord.

- International Space Station

- Russian 3D bio-printer 'Organaut' created the thyroid gland of the experimental mouse on the International Space Station under zero gravity.

- Navy ship

- USA Navy tested manufacturing technologies of 3D printing to rapidly manufacture ship parts on July 1, 2014.

- Aerospace

- NASA is expected to complete the first telescope, with all components manufactured through 3D printing technology. NASA has therefore become the first one to use 3D printing technology to manufacture the entire instrument.

- On October 11, 2014, a team of British 3D printing fans 3D printed a rocket. They are also preparing to launch the world's first printed rocket.

- Russian technology group used 3D printed a drone prototype, weighs 3.8 kg, with a wingspan of 2.4 meters. It can fly 1 to 1.5. Hours, with a speed of 90 to 100 kilometers per hour.

- Construction

- Many buildings start to be 3D printed all over the world in 2014.

- Automobile

- The world's first 3D-printed car is called called Strati, which is a small two-seater family car designed and built by Thelal Motors

- Electronics

- The first 3D printed laptop was launched in 2015.

- Clothing

- 3D printed clothes can fit women very well. A Massachusetts-based company has successfully used 3D printing technology to make a skirts.

-

3D printer make it possible to develop prototypes quickly and more accurately than traditional methods.

Easier: You may design the mold as you wish, then the 3D printer will turn them into a real object. It is more easier connect designing with a real object

Faster: 3D printer help to speed up both prototyping and production processes. Creating mold is not necessary, which saves much time for you.

Less expensive: 3D printer can produce different objects without spending money to create specific tool.

Better Quality: 3D printer is possible to build up the object step-by-step, which guarantees enhanced designs and eventually better quality objects.

Customization: You only need to change the mold file on your computer as the wish of your customer, then you got the customized product.

Flexibility: It is available to 3D print the whole complex or just print part of them. You can control them on your computer.

Friendly: It is easy to find way to learn the technology of both software and hardware of 3D printer.

Geometric Shaping Freedom: Product is not limited by traditional mold shaping ability.

Less material wasted: 3D printer only pipe out material as planned, which leads to very little waste.

-

Charles Hull developed the first commercial 3D printing press in 1986.

Massachusetts Institute of Technology was granted a patent for 3D printing technology in 1993.

ZCorp obtained the authorization from the Massachusetts Institute of Technology and began to develop 3D printers in 1995.

The first high-definition color 3D printer Spectrum Z510 was produced by ZCorp in 2005.

The team of Jim Kor created the first car printed by 3D printer in 2010.

Engineers in the University of Southampton developed the first 3D printed aircraft in 2011.

In November 2012, Scottish scientists used human cells to print artificial liver tissue using a 3D printer for the first time.

3D printed metal pistol was created by a 3D printing company based in Austin, Texas in November 2013, SolidConcepts. 3D printed guns is legal in the United States from August 1, 2018.

The staff of University of California San Diego used rapid 3D printing technology created a spinal cord stent that mimics the structure of the central nervous system.

On December 10, 2018, Russian astronauts used the 3D bio-printer to print out the thyroid gland of the experimental mouse on the International Space Station under zero gravity.

On April 15, 2019, researchers from Israel Tel Aviv University used the patient's own tissues as raw materials to 3D print the world's first "complete" heart with cells, blood vessels, ventricles and atria

-

3D Printer make it possible to turn a concept or mold into reality faster and cheaper than you expected.

The printer and 3D printing technology will go on to transform every industry and change the way we work and live in future.

Researchers from Tel Aviv University in Israel used the patient’s tissues as raw materials to produced a 3D printing heart with cells, blood vessels, ventricles and atria in 2019.

- Diamond Tools <<<

- 3D Printer >>>

- Laptop

3D Printer

Description

Profile

Photo

Introduction

Classification

Detail

Application

3D printing technology and 3D printer is often used to make models based on digital model in computer, and then it is used in the direct manufacturing of some products.Now it has applications in industrial design, architecture, engineering, automotive, aerospace, dental, education, medical industries, jewelry, footwear,etc.