Lathe

Description

-

Lathe definition, classification, lathe providers, history and main parts of lathe are presented on this page

Profile

-

Being a machine tool, Lathe can cut, drill, sand or knurl a workpiece based on an rotating axis. The main material of workpiece covers metal and wood.

Lathe makes shaping work simple and efficient.

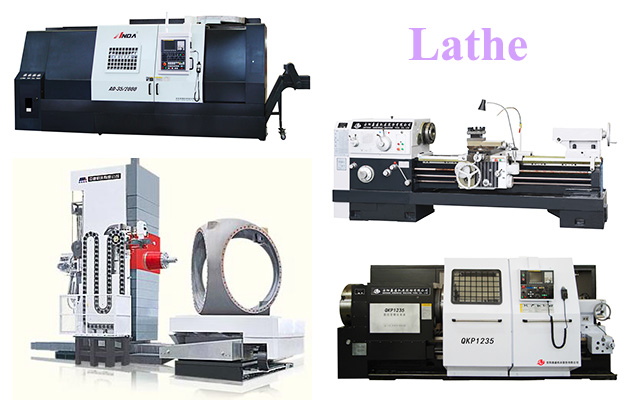

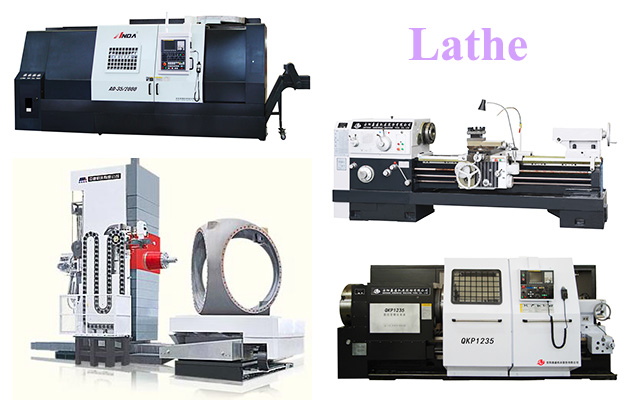

Photo

-

-

This lathe photo shows main types of lathe machines.

Introduction

-

A lathe machine cut down unwanted material by lathe tool when the workpiece rotate around an axis. A nicely shaped workpiece left when the lathe complete its job.

A normal Lathe machine can complete the following operation: turning, Drilling, facing, parting, reaming, tapping, knurling, boring, etc.

The first CNC Lathe Machine tool (milling machine) appeared in 1951. It was proposed by Parsons of the United States to the US Air Force when developing a blade processing machine for inspecting the profile of aircraft propeller blades.

The first automatic line composed of CNC machine tools was produced by the British Maurings Machinery Company in 1968.

Applications

-

The Applications of Lathe Machine are as follows:

Lathe use to make round or partially round parts.

It uses to cut male and female threads.

Use for cut-off material.

Lathe machine uses in Bore and drill holes or Knurl a knob.

Polish a surface of a round part and Taper a shaft.

Face or dress rough stock.

I use my mill for milling, but it is possible to mill small parts on a lathe. Chuck up a cutter and clamp the part on your tool post.

Power things like a hydraulic pump that have no motor. I can set the direction and speed of any shaft that fits in my chucks.

I work strictly in metal, plastic, and wood, but there are few practical limits to materials that could be worked on a lathe.

Align 2 pieces of a broken shaft prior to repair.

Bevel an edge.

Advantages

-

The Advantages of Lathe Machine are as follows:

The accuracy is very high in the case of CNC lathes compared to Normal Machining lathes.

The production rate is high.

No need for highly skilled operators.

Full automation, allowing for easier, quicker work.

The machining in the lathe and CNC lathe was very fast.

Highly versatile, allowing for use in the creation of all kinds of products and parts.

Disadvantages

-

If maintenance was not good, it would damage the parts of the machine by not using lubrication.

The device also wears off rapidly, if the operator is not good enough to handle the experiment.

Due to the speed of the bite, the smell will be very high in the atmosphere which also affects health.

These machines were more expensive than other conventional machines as you can perform almost all operations on a lathe.

Classification

- Lathe covers :

- CNC Lathe, automatic lathe,

- Turning lathe,

- Horizontal Lathe Machine,

- Horizontal Cnc Lathe,

- vertical Lathe,

- Metal Lathe Machine Woodworking lathe

- Processing Accessory

- Chuck CNC Lathe

- Centre CNC Lathe

- Guide Rail

- Inclined Guide Rail

- Horizontal Guide Rail

- Tool Holder

- Single-tool Holder CNC Lathe

- Double-tool Holder CNC Lathe

- Power Source

- Hydraulic Pressure

- Joint Drive

- Mechanical Drive

- Controlling Mode

- Artificial

- Setting Mode

- Floor-type

- Table

- Certification

- CE

- RoHS

- ISO 9001

History

-

The earliest prototype of a machine tool is a kind of Tree Lathe, which appeared around two thousand BC.

A worker step on the ferrule at the lower end of the rope, use the elasticity of the branches to make the workpiece rotate by the rope. A shell or stone piece was hold by hand as lathe tool to cut the work piece.

Around 1501, the Italian Leonardo da Vinci drew conceptual sketches of lathes, boring machines, thread processing machines and internal grinders. The structure of a grinder is also contained in the "Tiangong Kaiwu" published in the Ming Dynasty of China.

In 1774, the British Wilkinson invented a more precise barrel boring machine.

Modern Lathe

-

The first CNC Lathe Machine tool (milling machine) appeared in 1951. It was proposed by Parsons of the United States to the US Air Force when developing a blade processing machine for inspecting the profile of aircraft propeller blades.

The first automatic line composed of CNC machine tools was produced by the British Maurings Machinery Company in 1968.

- Connect buyers with suppliers.

- Home | Copywright @ SupplierV.com